XT-FGJ100S型 手动封罐机

Model XT-FGJ100S Manual Can Sealing Machine

XT-FGJ100A型 电动封罐机

Model XT-FGJ100A Electric Can Sealing Machine

XT-FGJ100C 型 电动封罐机

Model XT-FGJ100C Electric Can Sealing Machine

使用说明书

Operation Manual

(在使用前请详细阅读本说明书并妥善保管)

(Please read this Manual before operation and keep it properly.)

目录

CONTENTS

1.产品简介

1. Product introduction

2.面板及各按扭开关说明

2. Description of panel and button switches

3.结构、部件名称及说明

3. Name and description of structure and components

4.特点及主要技术参数

4. Characteristics and main technical parameters

5.机构原理及调机操作方法

5. Mechanism principle and commissioning method

6.安全操作注意事项

6. Safety precautions

7.保养、维护与厂家服务

7. Maintenance and manufacturer services

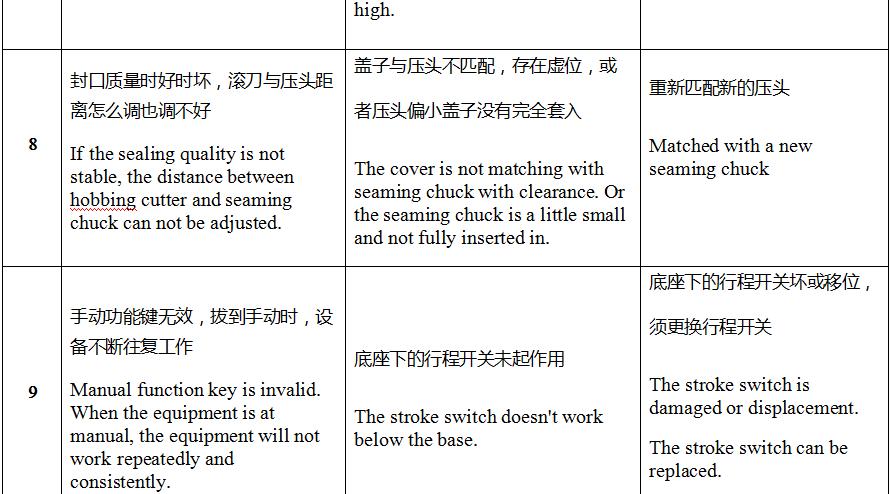

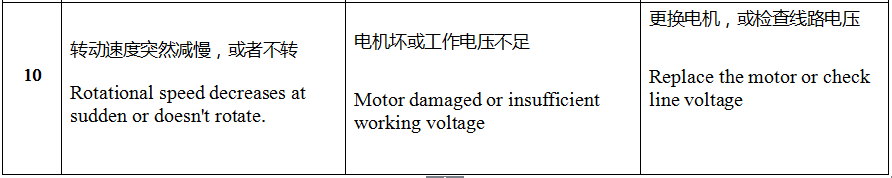

8.常见异常现象及其排除方法

8. Common anomalies and troubleshooting

1.产品简介

1. Product introduction

1.1本产品主要适用于各种圆形的PET塑料、铁质、铝质及纸质罐等的封口包装,产品设计先进、结构合理,并且操作简便轻巧,是食品、医药、茶叶和化工等行业的必备理想包装设备。

1.1 The product is mainly applicable to sealing and packaging of various kinds or round PET plastic, iron, aluminum and paper cans etc.. The product is characterized of advanced design, reasonable structure, easy and convenient operation. It is an ideal packaging equipment for food, medicine, tea, chemical industry and other industries.

1.2本产品主体采用全不锈钢材料,外形美观,符合大多数标准生产车间设计要求。

1.2 The main body of the product adopts full stainless steel with beautiful appearance. It complies with design requirements of most standard production workshops.

1.3采用单电机工作,各零部件加工精密,生产技术和工艺等经过本公司长时间沉淀和不断改良,有着噪音小,故障率低的优点。

1.3 It adopts single motor. All components are precisely manufactured. The production techniques and processes have advantages such as small noise, low failure rate after long-term precipitation and continuous improvement of the company.

1.4本产品均符合国家标准、部颁标准、企业标准的规定,并经严格检查和测试全格后,才许可出厂。

1.4 The product can only be approved for delivery after being tested as in line with relevant national standards, ministry standards, standard provisions of the company, and as acceptable after strict inspection and testing.

实照图:

Equipment diagram

XT-FGJ100S XT-FGJ100A XT-FGJ100C

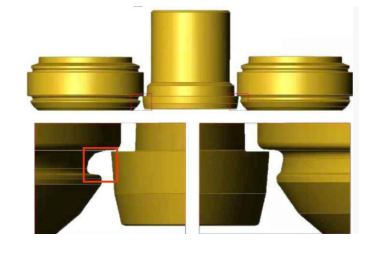

2.面板及各按扭开关说明

2. Description of panel and button switches

绿色按钮 Green button

红色按钮 Red button

电流表Amperemeter

红色指示灯Red indicating light

绿色指示灯Green indicating light

电源指示Power indicator

运行指示Running indicator

自动 Automatic

点动Inching

手动 Manual

急停 Emergency stop

开关 Switch

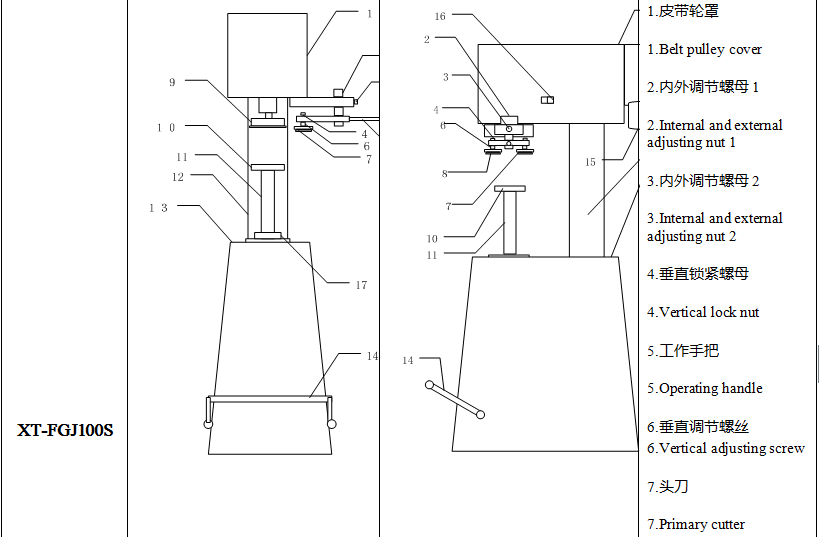

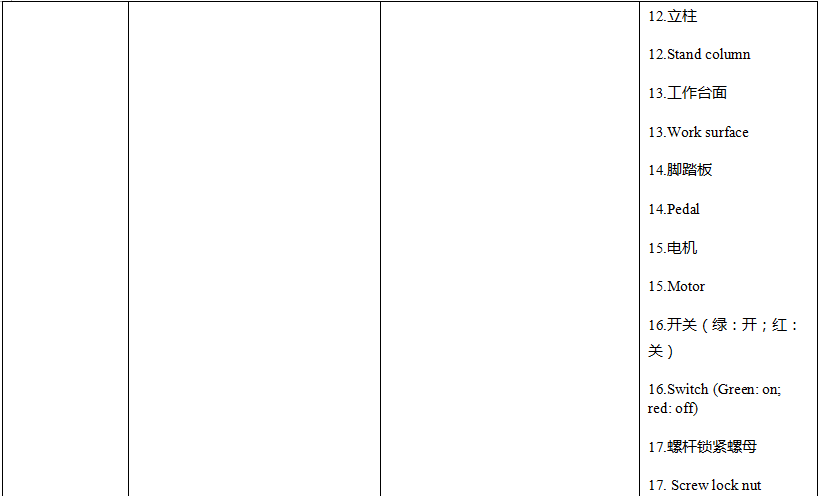

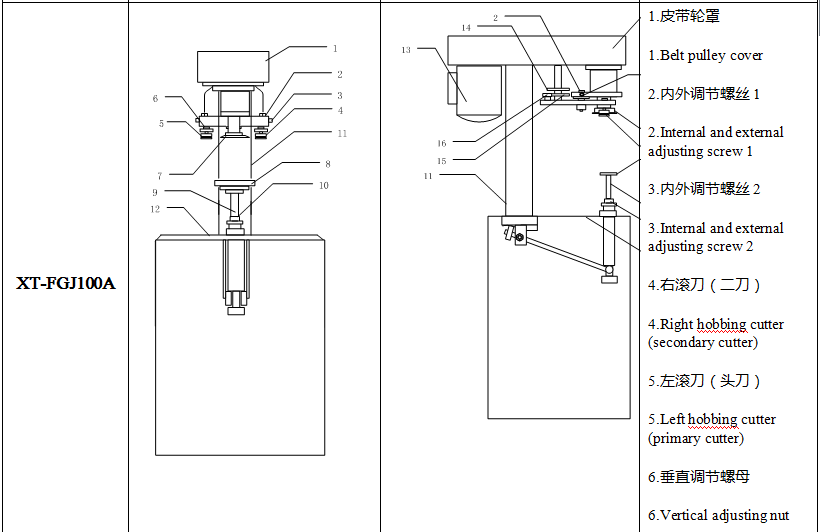

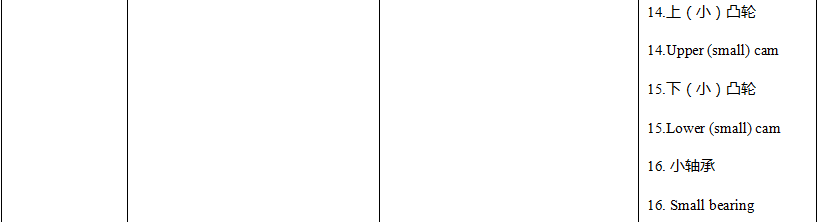

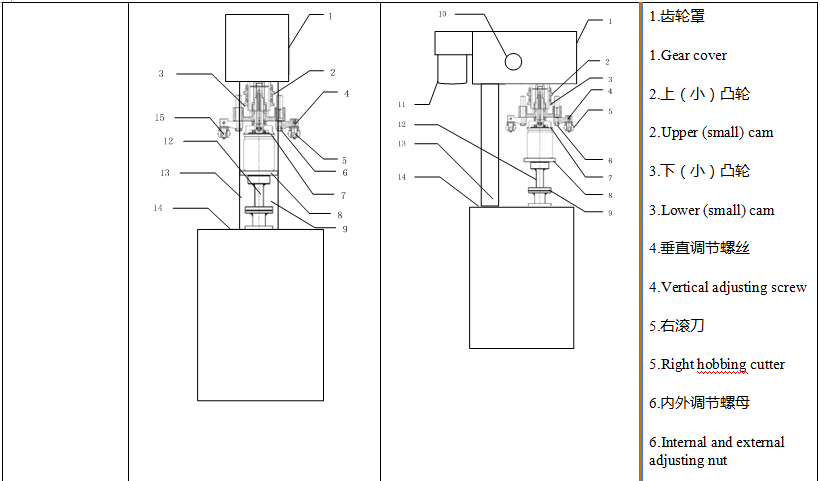

3.结构、部件名称及说明

3. Name and description of structure and components

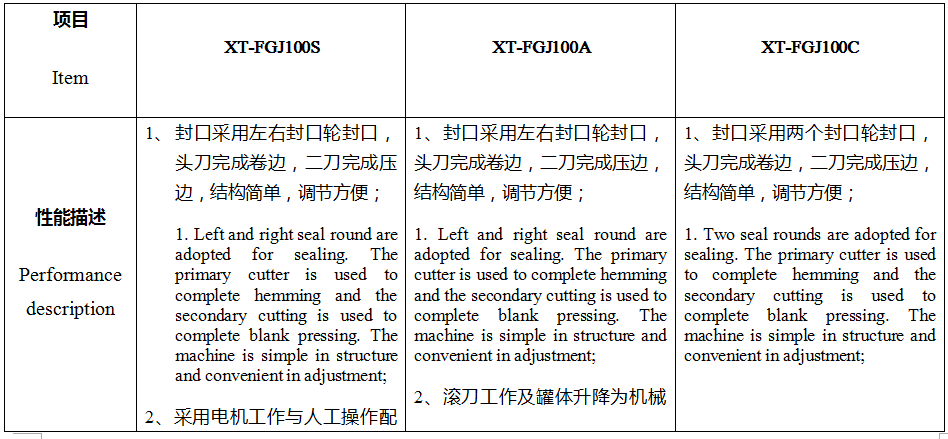

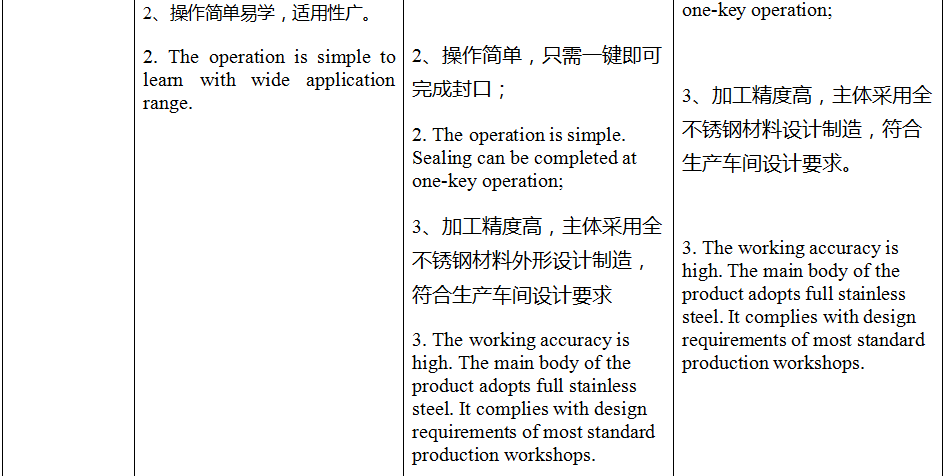

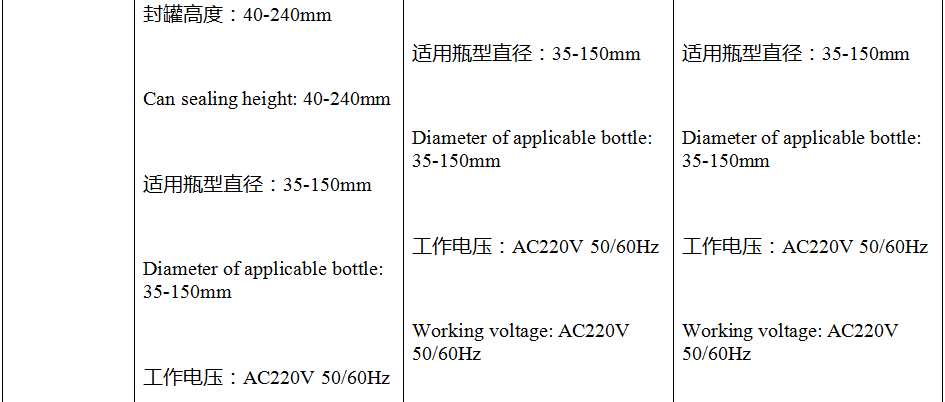

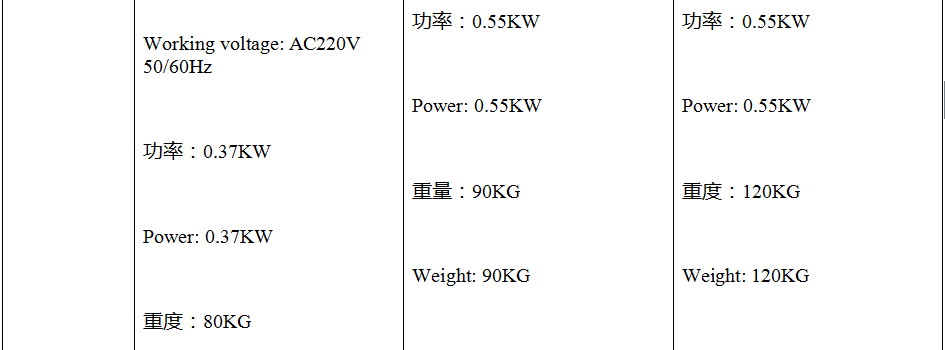

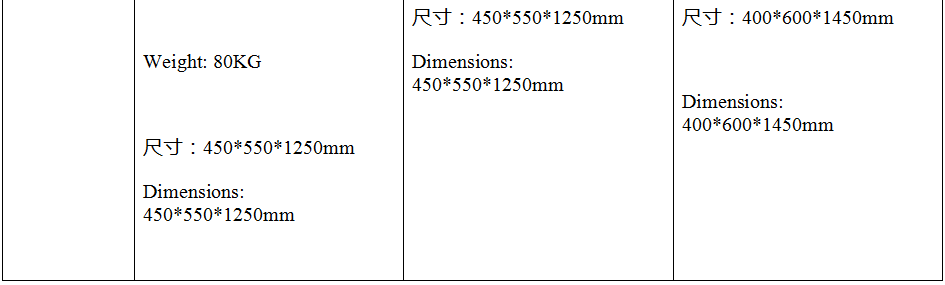

4.特点及主要技术参数

4. Characteristics and main technical parameters

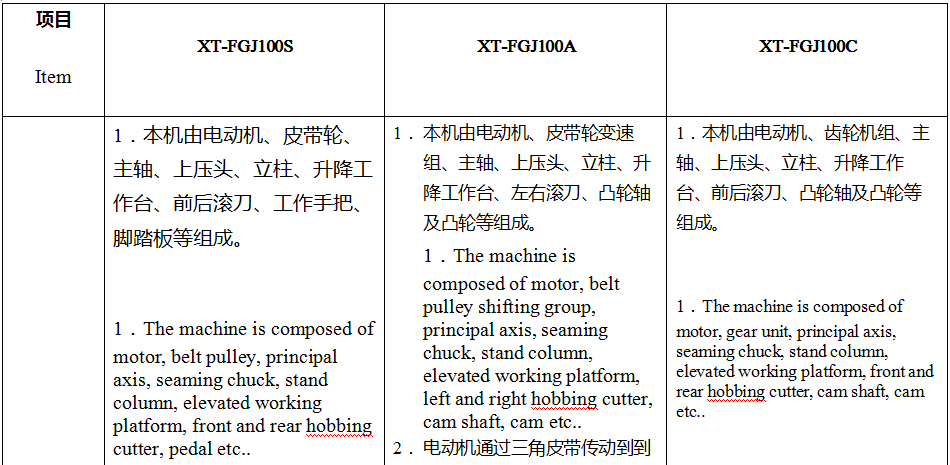

5.机构原理及调机操作方法

5. Mechanism principle and commissioning method

5.1.机构原理及开机流程

5.1 Mechanism principle and start up procedure

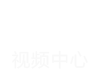

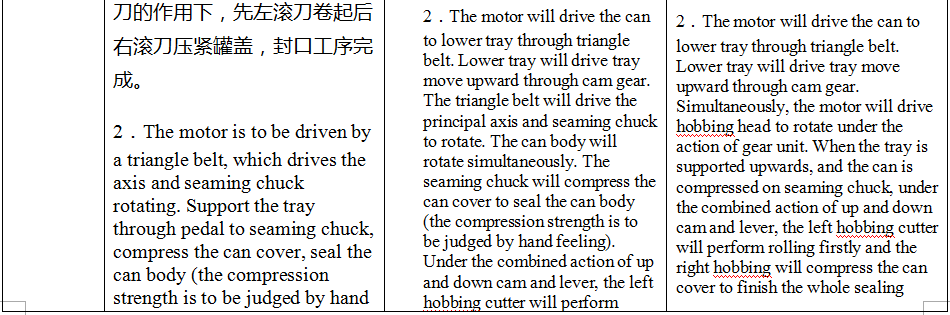

该设备采用二重卷封原理,利用盖边与罐边经过咬合折叠压平的步骤,从而达到密封的效果。形成步骤如下:

The equipment adopts double rounded seam to achieve sealing effects by occlusion, folding and pressing of cover flange and can edge. Forming steps are as following:

(1)将罐盖盖于罐胴头上,使罐缘嵌合于罐盖之盖缘内侧开口部。

(1) Put the can cover on trunk head. Make the can edge inserting to the opening at cover flange internal side.

(2)利用托罐盘压力,将罐身向上托,使罐盖嵌合于轧头。

(2) Support the can upward relying on tray pressure to make the can cover being inserted to roller head.

(3)第一卷轮向内包卷盖缘,一面绕着盖缘作相对的旋转运动,一面向轴心施加压力。

(3) The first roll will envelop cover flange inwards. One surface will make relative rotation around the cover flange, and the other surface will apply pressure to the axis.

(4)第一卷轮完成动作后,第二卷轮接着将第一卷轮所形成的第一卷封压紧而成第二卷封时,卷封工作完成。

(4) After the first roll finished its job, the second roll will compress the first layer of rounded seam thus to form the second layer of rounded seam. The whole founded seam operation has been done.

(5)托罐盘向下,轧头向下压退出空罐。其形成步骤如下图所示:

(5) Support the can tray downward. Roller head will press downward to exit empty cans. Forming steps is as shown in the following Fig.:

头道滚轮 Primary roller

盖钩 Cover hook

身钩 Body hook

压头Seaming chuck

二道滚轮 Secondary roller

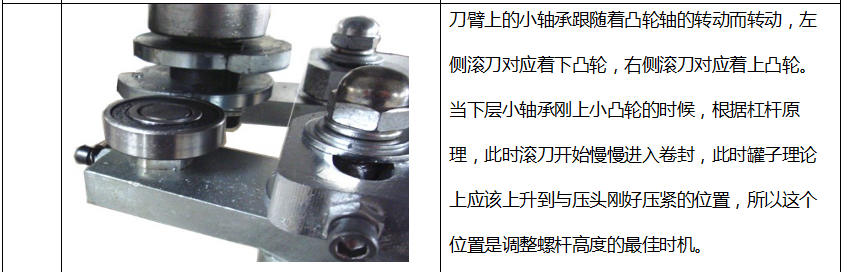

!特别注意:滚刀分为两把滚刀,第一刀为卷刀,主要有卷边的作用,第二刀为压刀,主要有压边的作用。所有机型的滚刀运行顺序,都是第一刀先进入并完成后,再到第二刀进入工作。

!Special attention: Hobbing cutter can be classified as into two types. The primary one is rolling cutter, which mainly plays a role of seam rolling; the secondary is pressing cutter, which mainly plays a role of edge pressing. For all hobbing cutter operation sequence, the primary will start first and followed by the secondary cutter.

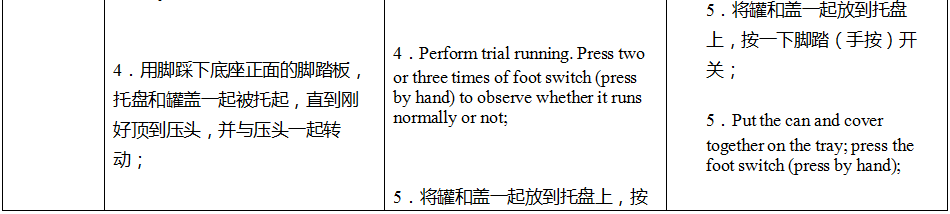

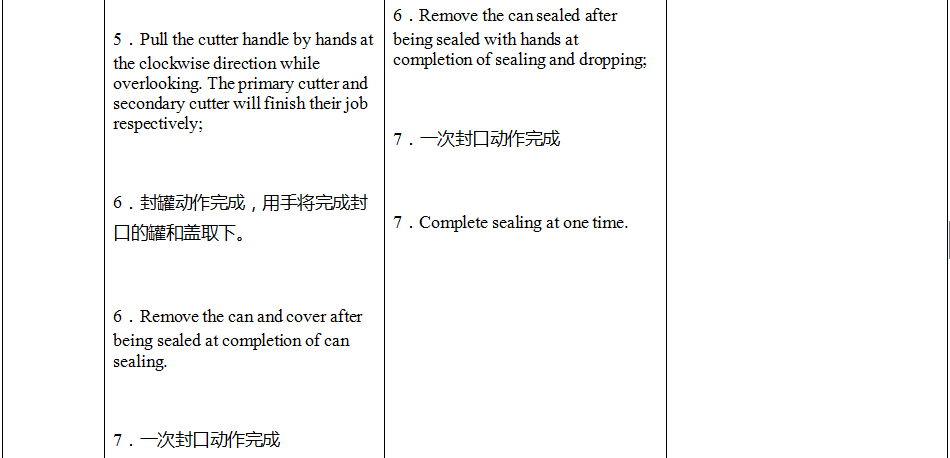

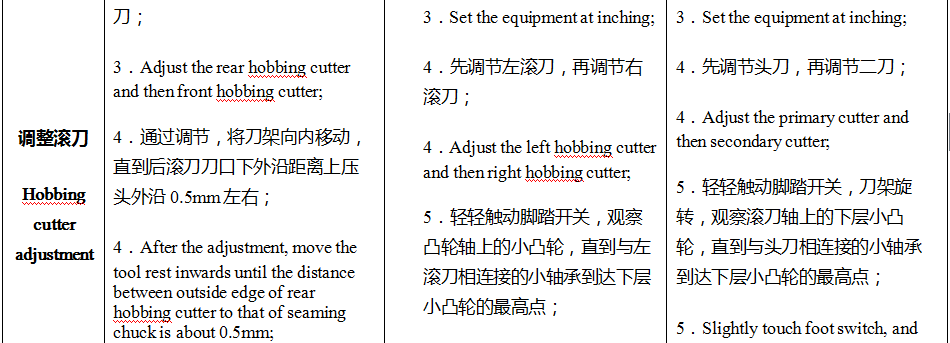

5.2调机操作方法

5.2 Commissioning method

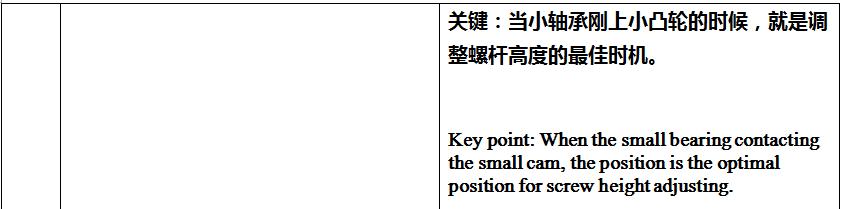

5.3.调机要点及图解

5.3 Key points of commissioning and illustration diagram

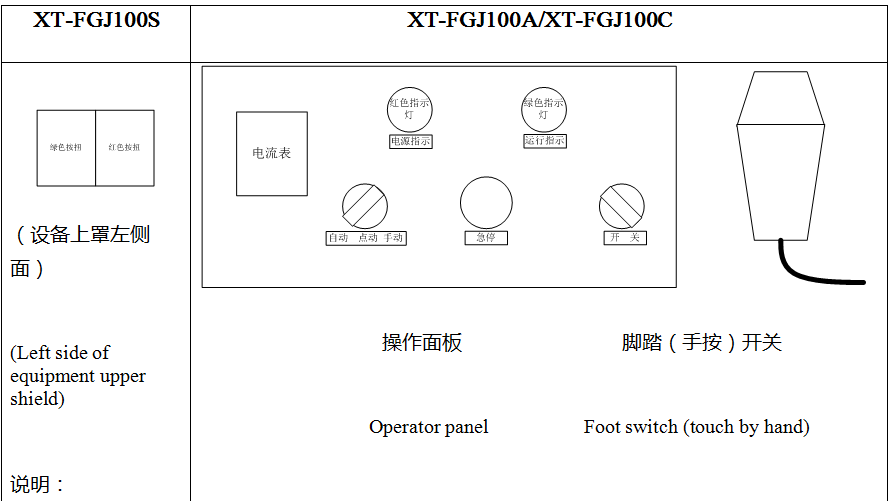

6.安全操作注意事项

6. Safety precautions

6.1使用前将应检查各指示灯是否正常。

6.1 Check whether the indicator light is normal or not before operation.

6.2各转动部位要定时或定期加注润滑油。

6.2 Fill lubricating oil periodically for rotating parts.

6.3工人在操作前应进行操作培训,学习设备的操作注意事项。

6.3 Workers should be trained before operation training to learn the matters needing attention.

6.4作业前要将轮子固定,并保证设备不会滑动。

6.4 Fix the caster before operation and ensure that the equipment will not slide.

6.5在进行作业时建议戴上手套防护。

6.5 It is suggested to wear protective gloves at operation.

6.6在进行作业时不可慌张,切勿将手指放入高速转动的卷刀架,以防伤手。

6.6 Do not feel nervous at operation. Do not put your fingers into high-speed rotating roll tool rest to avoid damage to hands.

6.7发现异常情况应立即停机检查,排除故障。

6.7 It is necessary to stop the machine immediately for troubleshooting.

6.8在进行封罐操作时,在将罐盖放入到托盘时,手指不能放到盖面上,以防设备误伤手指。

6.8 When put the can cover to tray at can sealing process, do not put fingers on the cover avoid damage to hands.

6.9当设备暂停使用时,务必要将脚踏开关放到安全的位置,并把开关拔到“关”的状态。

6.9 When the equipment is suspended for use, please do not put foot switch on a safe position. Pull the switch to "off".

7.保养、维护与厂家服务

7. Maintenance and manufacturer services

用户若能按照本说明书的规定,正确使用和维护封罐机,可达到运行可靠,延长使用寿命的目的。

If the user can use and maintain the can sealing machine according to the provisions of the Manual can run the equipment reliably and extend service life.

7.1操作者应当了解封罐机工作基本原理、性能和操作要点。

7.1 The operator should know basic principle, performance and operation points of can sealing machine.

7.2当班主管负责监督操作者正确、合理使用封罐机及日常维护。

7.2 Shift supervisor shall be responsible for monitoring whether the operator used the can sealing machine correctly and performed daily maintenance reasonably.

7.3操作要点及注意事项:

7.3 Operating points and precautions:

7.3.1检查各部件是否润滑良好,各紧固件有无松动。

7.3.1 Check whether all components are in good lubrication status and whether fasteners loosened or not.

7.3.2 检查各固件有无松动,电源线有无破损。

7.3.2 Check whether fasteners loosened or not and whether the power line is damaged or not.

7.3.3 搬动封罐机时,必须三人以上在确保安全的情况下方可进行。

7.3.3 Can sealing machine should be handled by more than 3 person to ensure safety.

7.3.4严禁拉扯和压电源线。

7.3.4 It is strictly prohibited to pull and press power line.

7.3.5 严禁用水冲洗机体(只可用湿布擦洗)

7.3.5 It is strictly prohibited to rinse the machine with water (can only wipe the machine with damp cloth)

7.3.6严禁敲打压盖、托盘和滚刀。

7.3.6 It is strictly prohibited to beat gland, tray and hobbing cutter.

7.3.7因机架内部依靠多个齿轮及导杆进行变速及传动完成设备运作,每天在机器运行前,要通过维护孔往齿轮加注黄油,或者打开底架门在导杆螺杆上加注黄油。

7.3.7 Since the rack conducts speed changing and transmission relying on multiple gears and guide rod, fill butter to gear through maintenance hole or fill butter to guide screw opening chassis door before operating every day.

7.4 本设备由厂家质量保修一年,保修时请提供发票、收据或者设备上的合格证照片。

7.4 The manufacture will provide one-year warranty for the equipment. Please provide invoice, receipt and photo of quality certification on the equipment.

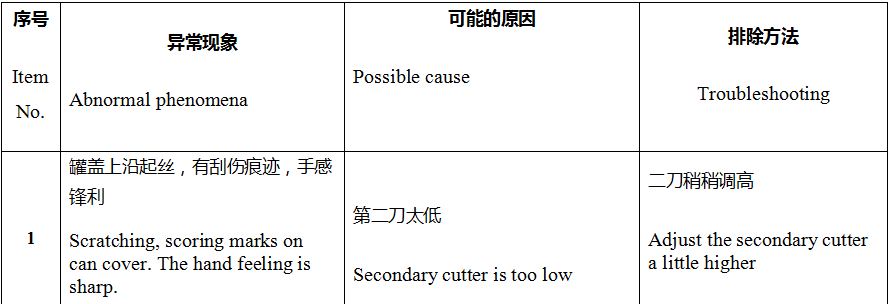

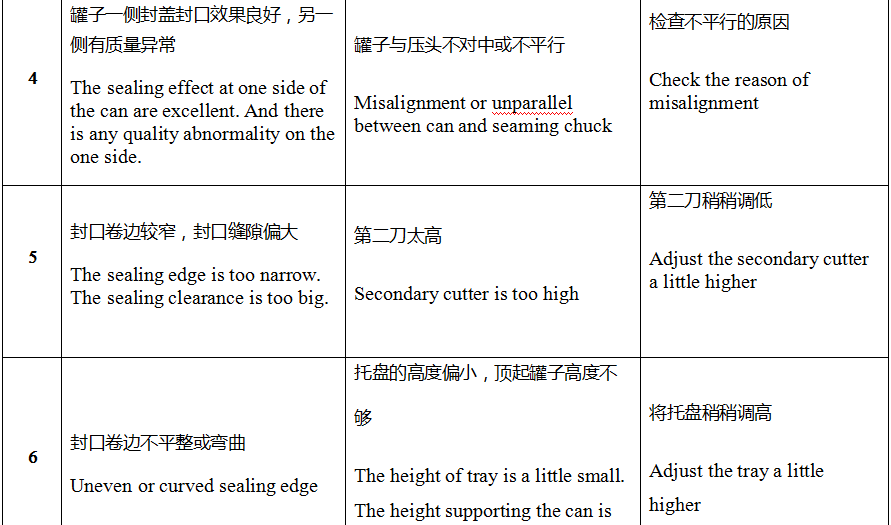

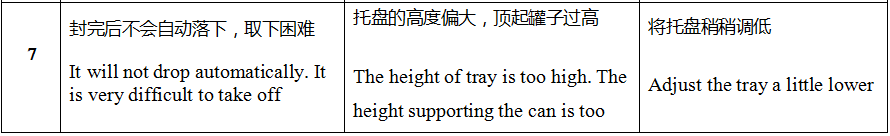

8.常见异常现象及其排除方法

8.3 Common anomalies and troubleshooting

XT-FGJ100S

XT-FGJ100A

XT-FGJ100C

使用说明书

Operation Manual

在使用前,请仔细阅读此说明书并妥善保管。

Please read this Manual before operation and keep it properly.

注:本说明书上的所有内容均经过认真核对,如有任何印刷错漏或内容上的误解,最终解释权归本公司所有;所购买产品,请以实物为准。

Note: Please check all contents on the Manual carefully. For any printing error or misunderstanding on the contents, the company owns the final explanation right; for the products purchased, the real object shall prevail.